The Wichelhaus Group is the specialist for the development and realization of complete solutions for textile machines and automation for small medium-sized companies to global players.

In the textile machinery sector, we develop, design and build state-of-the-art dyeing systems, so-called “jiggers”, for woven and knitted fabrics. With our ecological high-end solution “Vario Line” with a 30% lower energy consumption, the most difficult woven fabrics can be further processed. If required, we can upgrade our customers’ existing plants to the latest drive technology. “State of the art” automation solutions up to the planning and realization of the use of robot technology for the infeed and outfeed, as well as laboratory technology complete our offer.

With innovative engineering, Wichelhaus increases the efficiency of the dyeing machines - increasing productivity, optimizing quality or securing and improving ecological standards while maintaining a balance between ecology and economy.

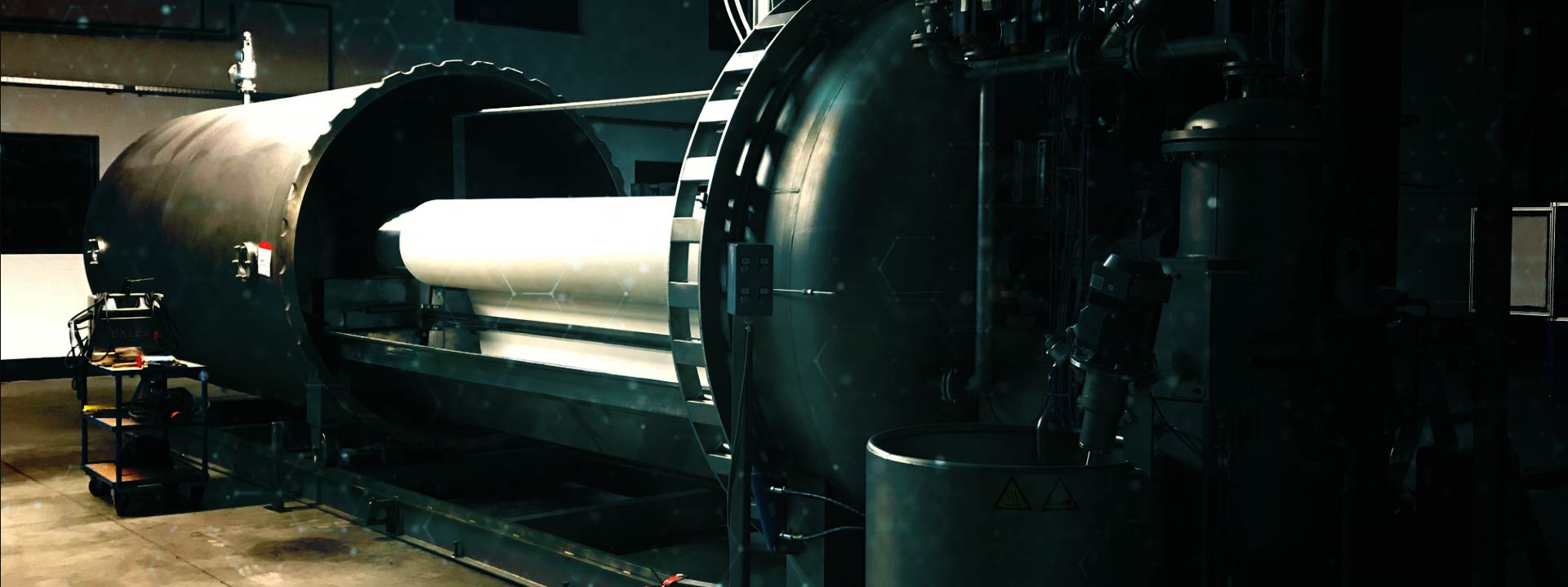

The Vario Line HT (high temperature 143°C.) is made in high quality stainless steel and reached a high degree of process security, durability, flexibility and economic for Polyester and mixed fabrics in width`s to 4000 mm The very well controlled fabric tension (0-1000N) steeples adjustable allow a perfect dyeing of different fabric types (Polyester and mixed fabrics) and fabric qualities. In order to ensure a uniform absorption of the dyestuff over the entire width of the fabric the machine is equipped with two independents of each other expander which secures a constant bending angle of the goods. Different batch diameter (800 / 1200 / 1400 mm) allows higher capacity dyeing processes which are not possible on beam dyeing machines, special impermeable fabrics. The Vario Line high temperature Jigger is built with roller widths of up to 4000mm.

Details:

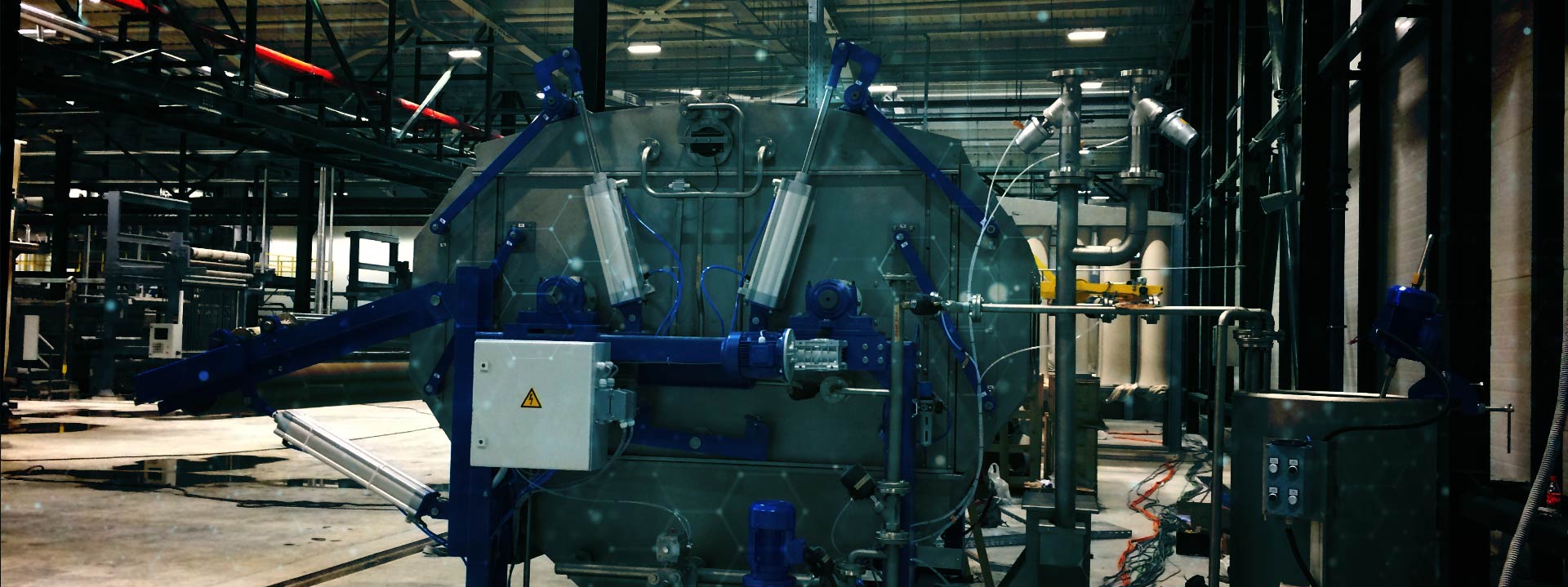

The ULTRA Jigger with the robust and compact construction is the result of modern engineering. This universal precision Jigger is for dyeing, washing & bleaching of woven goods such Nylon, Viscose, Cotton, Acetate, Perlon, Silk etc. Even for heavy cotton and delicate fabrics the ULTRA Jigger give the guarantee of constant fabric tension (0-1000N) and employs the energy use rationally by latest control technology. The reliable and well- known Wichelhaus driven- and process technology is also use here. Temperature, constant tension & speed, exactly dosing and favorable liquor ratio are some of the important points in order to achieve best fabric quality. Controlled monitoring of dyeing process offers optimum safety. The ULTRA Jigger fulfils each of the requirements, is economical, user-friendly, environmentally and inexpensive.

ULTRA Jigger advantages:

Ultra Jigger equipment:

Due to the fact, that these equipment are running since decades in the factories often the machine control system ore the winding technology is not state of the art anymore. We offer to our customers a variety of upgrades and retrofits for their textile machinery equipment.

The upgrade package can be used for all Jigger brands and for atmospheric and also high temperature Jigger.

Technology:

Advantage:

AUTOMATION

Intelligent machine concepts, the focus always on the continuously increasing customer requirements for process automation as well as the minimization of life cycle costs are our core competences in the field of automation.

For us, the product and the process always determine the level of technology used. Which automation systems and which degree of automation are finally implemented is done individually in coordination with the customer. In this way, we achieve the highest level of dynamics and quality with our solutions at low personnel costs.

ROBOTIC APPLICATIONS

In state-of-the-art factories handling tasks are more and more carried out with industrial robots than with conventional methods. A significant advantage over manual handling, in addition to the cost savings, is the high flexibility provided by the use of modern robots. Subsequent changes or expansions of the functionality can be implemented easily and inexpensively. With the Wichelhaus Group you have an experienced partner, both in terms of project planning and programming, as well as in the area of attachments and grippers. With our 3D construction and simulation software, robot applications can be tested as a “virtual prototype” before construction begins. This reduces errors and saves time during commissioning.

The next generation

Many customers want to know more details about the actually status of their “real-time” of production. Nowadays, “Just in time” production, a reducing latency, in the event of machine malfunction is a very critical factor. We are able to support you professionally to the right way of “Industry 4.0” and to refine your “Big Data” to “Smart Data”. It will help you to generate knowledge from data.

Very often there are differences found in the shade when recipes are transferred from lab to bulk. In order to achieve the results in a “right-first-time” attempt, our team of technologists and engineers has developed the Vario Lab Jig. Identically to the Vario Line Jigger for large scale production this laboratory machine was down scaled without loss of any features. The Vario Lab Jig is perfectly suitable for obtaining lab recipes, which will not cause any variation in production afterwards. Furthermore the Vario Lab Jig is an outstanding alternative for sampling for your next collection. Last but not least, the Vario Lab Jig is a first class option for processing narrow fabrics. The liquor volume in the standard machine can be varied from 3,5 to 12 liters.

Specification:

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationThe Wichelhaus group is more than its individual companies and cooperation partners.

For our customers in the textile industry in China we have built up a network of specialized competence partners with

FYJ Fanyuan Instrument and

Dening Textile Technology Center.

THE SUM OF COMPETENCE,

MOTIVATION AND TEAM SPIRIT

Our employees work hand in hand in the Wichelhaus Textile Network in Germany and China. Driven by their desire for innovation and perfection, for highly developed, new and mature technologies. Only through the interaction of specialists can we meet the complex requirements of our customer industries and global markets.

Due to our curiosity and our incentive to see technical challenges also as an opportunity to learn, the experience in the team grows continuously and is reliably passed on to the young colleagues. Specialised knowledge on the one hand, teamwork on the other, that is what makes working with us interesting. From the order to the finished product on schedule, the coordinated cooperation of many people involved is necessary. We simply enjoy working together. This is how technology of the highest level is created.

Challenge us.